Different Types of Bulkhead Shaft Seals

If you design, build, own, operate or repair surface ships, chances are that you will run come across vessels that have rotating shaft equipment traversing through a bulkhead that must remain watertight. After all, it won’t float if it is taking on water. You know you need to specify, purchase, or install some sort of seal, but what type of seal do you need? And will it work?

Below you will find a breakdown of the different types of bulkead sealing equipment available on the market today:

- Pressure Activated Composite Rings

- Dry Carbon Seals

- HydroActive Seals

With this information you can compare and contrast their features and benefits and decide for yourself the most ideal solution for your application.

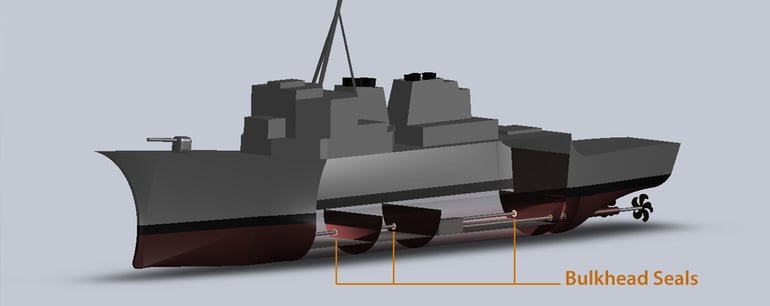

Bulkhead Shaft Seals Overview

No ship is impervious to water, and in the event that your vessel is taking on water, you need to stop the compartment to compartment flooding. Watertight bulkhead doors can be closed, static seals and weldments keep pipes and cable penetrations from leaking, but what about rotating equipment?

Static sealing is one challenge, but a whole new set of challenges is introduced when your equipment is rotating. With engine output increasing, and the waterjets becoming more prevalent, high horsepower, high RPM systems are becoming the norm, and making it more difficult to create a watertight seal that will last through several maintenence cycles.

The basic principle is the same across each different style -- Seal Water from one compartment to another to reduce the amount of water that the vessel can take on in order to maintain bouyancy.

A few common examples of today’s bulkhead seals include variations such as dry carbon rings which are a type of the mechanical face seal with a ring of carbon continually spinning with the shaft sealing against a static face. There are composite rings that are activated by pressure, either axially or radially, thus allowing them to run without contact in non-flooded conditions. Similar to this principle, but activated only by the sealing media which it is designed to keep out; water, the HydroActive is uniquely operated only by water and not pressure, thus reducing premature activation and wear.

The Different Types of Seals

Pressure Activated Composite Rings

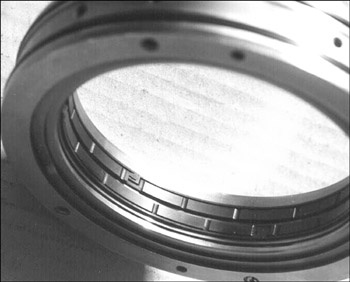

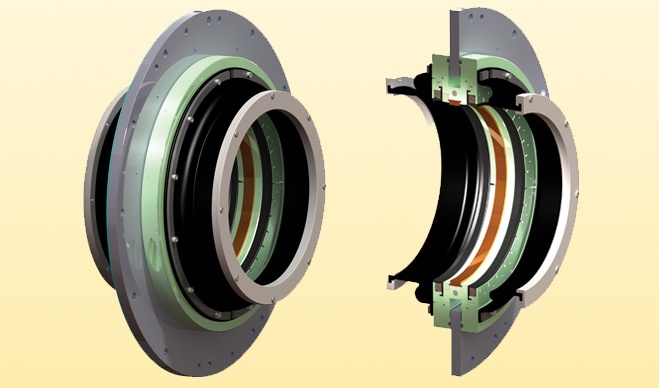

The basic design concept and intent behind these types of seals is adequate and in perfect environments would work just fine. Unfortunately in the marine industry, environments are anything but perfect, far from it in fact. While these seals are designed to be operated by changing pressure caused by head of water, slight changes in air pressure across compartments will also cause activation. In these conditions the seal is running dry for unknown periods of time wearing out due to friction, in some cases wearing so much that when they are called upon to seal out water, they are incapable, and allow massive volumes of water to pass between compartments, causing catastrophic failures. The image below shows a cutaway section of a common pressure activated, dry running composite ring.

Dry Carbon Seals

Utilizing the same principles as mechanical face seals but operating solely on the low friction properties of carbon graphite rotating against a static face, dry carbon seals are simply dry carbon rings spinning with the shaft against a machined axial face creating a watertight barrier. While effective, their propensity for creating abundant amounts of carbon dust, and carbon being highest on the list of noble materials create a breeding ground of corrosive potential.

These seals are designed to wear out, need replacement at set intervals and are not adequate for the rigors of high surface speeds seen with large shafts coupled with high shaft speeds. Companies such as RocCarbon (www.roccarbon.com) have many applications which are more demanding and require constant use, which may benefit more from the use of low fricion carbon.

HydroActive Seals

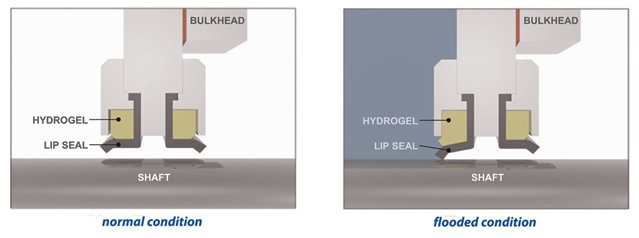

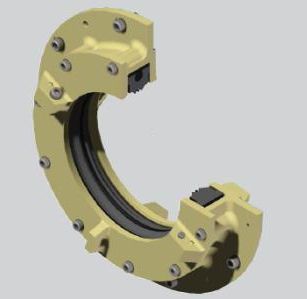

In order to combat all of the issues noted related to premature failure, wear, costly maintenence cycles, HydroActive seals are designed not to operate on the principles of pressure, instead the sole presence of water. Midé's HydroActive seal also utilizes a non-spinning configuration; less moving parts equals less wear and less things to break.

Midé's HydroActive technology drives an elastomeric lip seal only in the event of a flood, and are water cooled and precisely tuned to allow for full speed operation even while fully engaged. During dry operation, no items are in contact with roating equipment, and do not wear out providing the operator a long life system that requires minimal maintenence.

HydroActive technology is also unique in it's ability to set and re-set itself and to be used multiple times without needing to be replaced.

I hope you found this helpful. Please feel free to contact me with any questions.